Our Products

The Problem

Making repairs on under pressure water or wastewater lines can be a significant inconvenience.

The extremely high pressure inside the system means it would be dangerous for crews to attempt to work on it while in operation and traditional methods of repair require the system to be shut down, as water cannot flow through the pipe during time of repair. However, shutting down the entire system equates to service disruption for potentially thousands of homes, businesses, and critical infrastructures, like hospitals and emergency services. Additionally, system shutdown can lead to water contamination which leads to boil orders and loss of treated water.

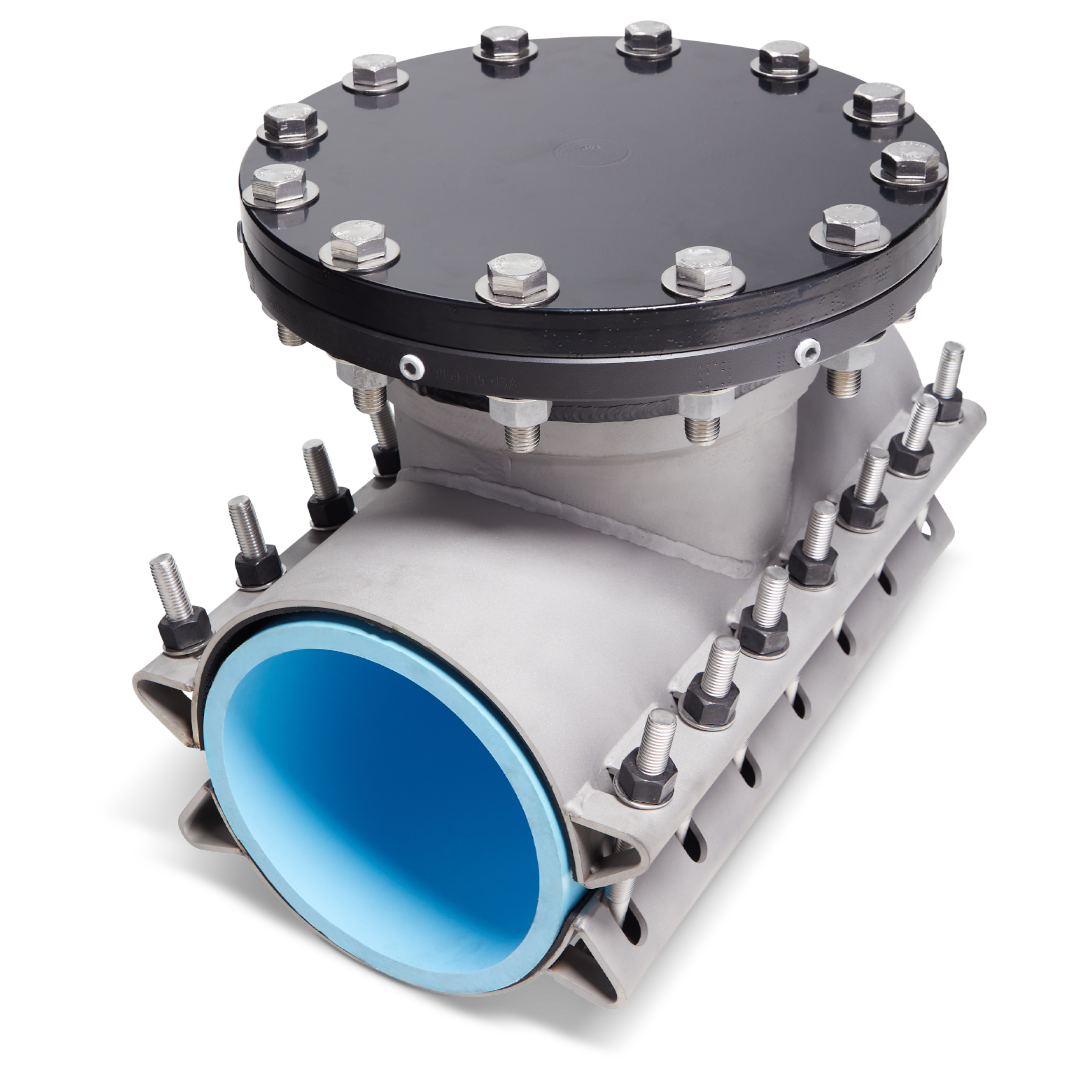

Fortunately, Hydra-Stop’s line stopping solution, the HSF 250, enable crews to isolate the pipe requiring service without disrupting pressure upstream of the stop. Thanks to our line stop fitting solutions, utility providers can perform necessary maintenance or repair work without dealing with the risks and interruptions associated with shutting down an entire system.

The Solution

Hydra-Stop’s HSF 250 line stop fittings utilize line-stopping techniques that temporarily plug a pressurized pipe without disrupting the service upstream of the stop. This is achieved by first making a hot tap into the water main, which allows the insertion of the device under pressure. After the repair work is completed, the operator disconnects the equipment and attaches the completion plug. The installation process is fast, easy, and safe, reducing the burden on workers and enabling them to restore service to affected areas with greater speed and efficiency.

Product Documents

Brochures

Specifications

Line Stop Fittings?

to receive an itemized quote.