CONTROL IS NOT A PIPE DREAM

Insertion Valves

Perform planned, routine, or emergency maintenance without a complete shutdown of your water and wastewater systems with Insta-Valve, our industry-leading valve insertion solution.

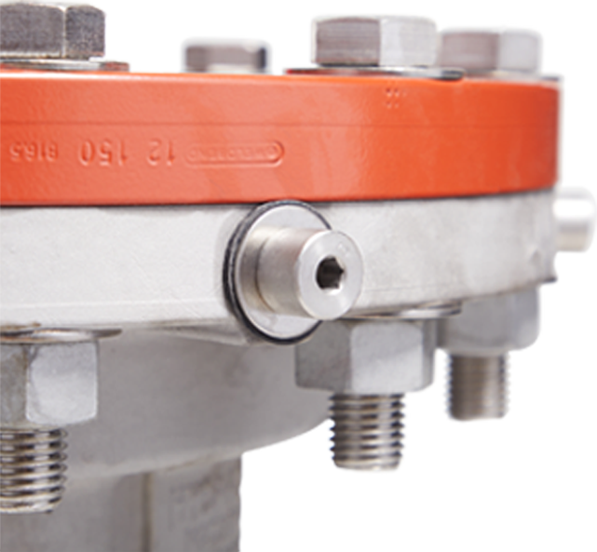

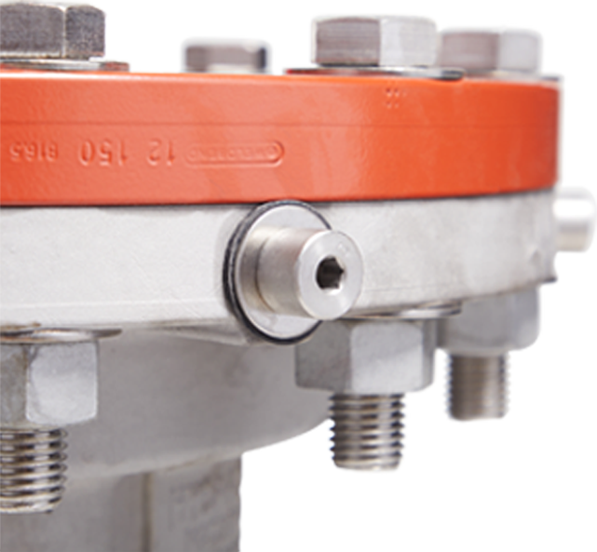

Stop the Line at the Repair

Line Stop Fittings

Line stopping temporarily isolates the section of pipe at the site of the repair or maintenance work, while keeping the remainder of the system in operation.

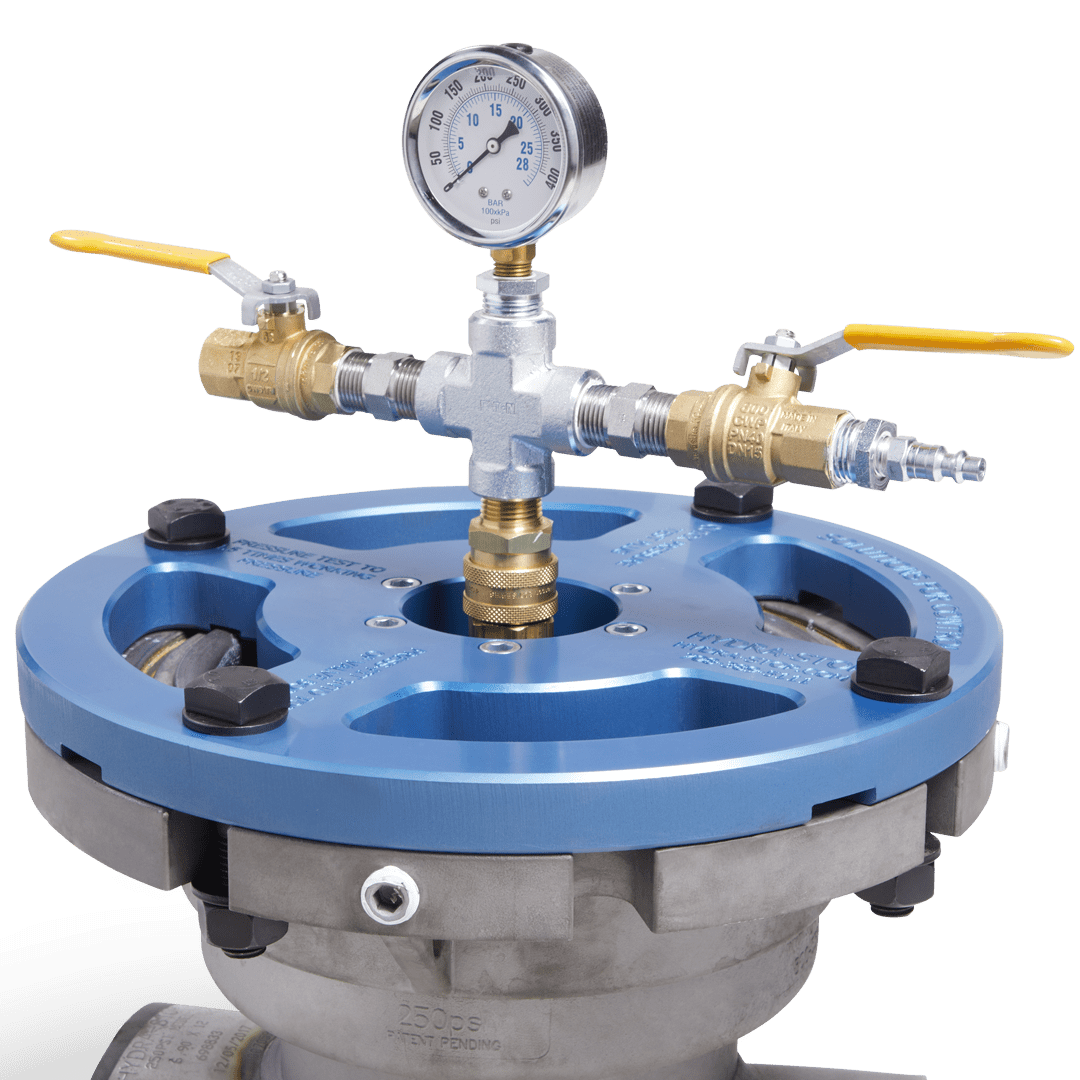

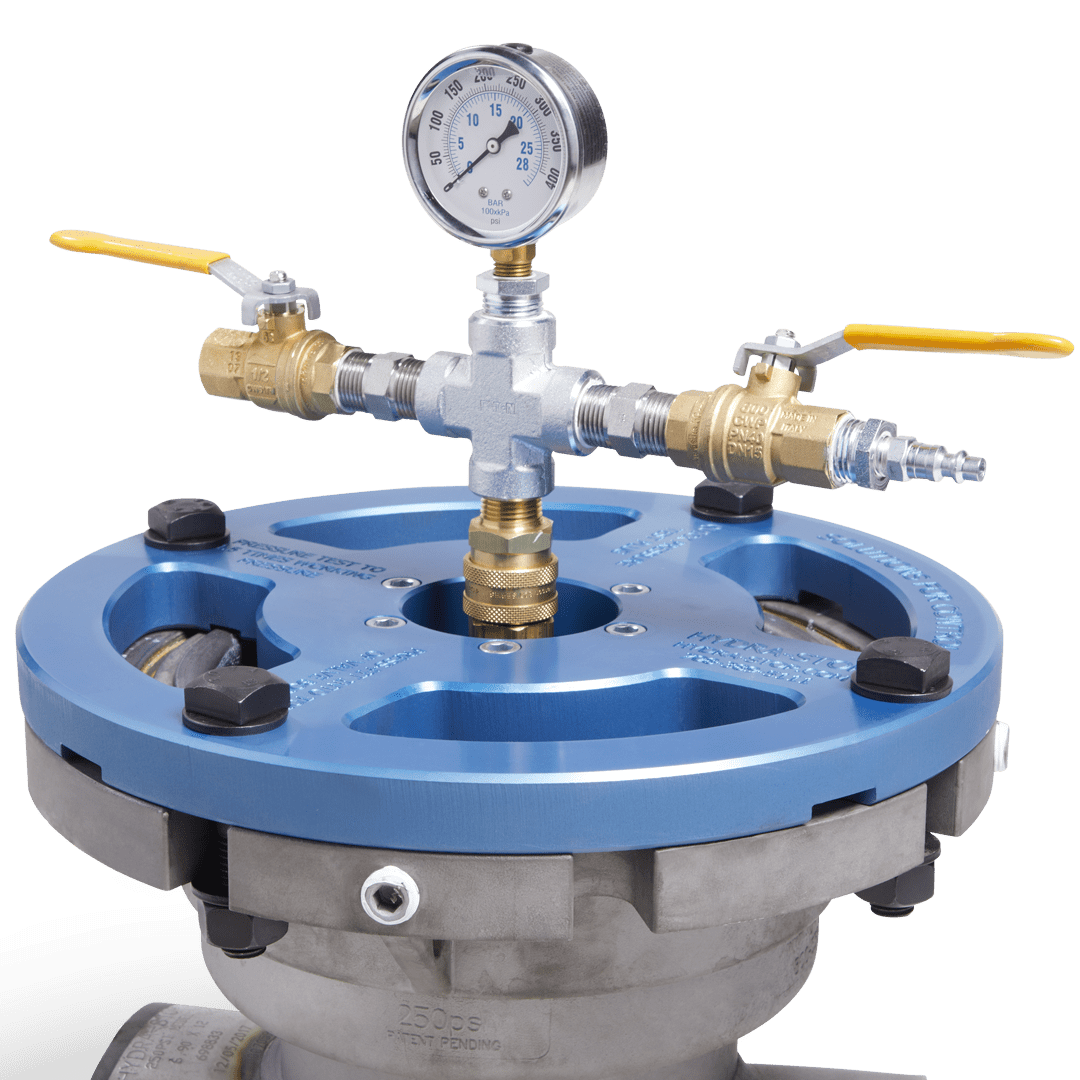

Tools for Quick and Easy Installations

The Equipment

The right tools for efficient and safe installation of Hydra-Stop solutions.

Curious about cost? Try out our ROI Calculator

Curious about cost? Try out our ROI Calculator

Try out our ROI Calculator

and how much will be needed

to get the job done.