How It Works

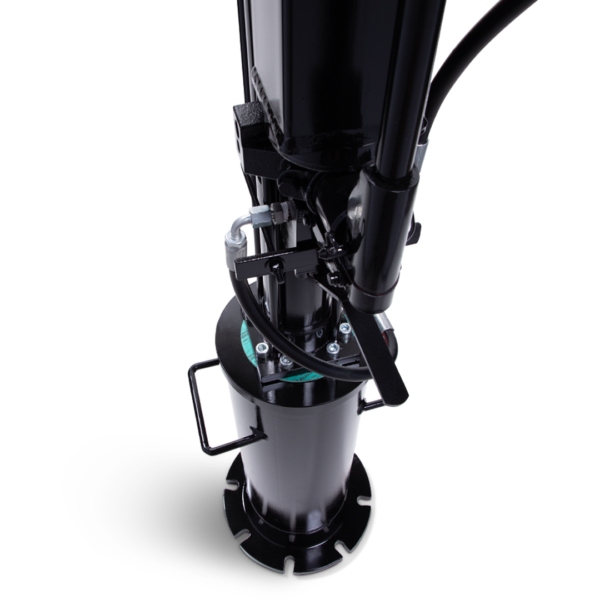

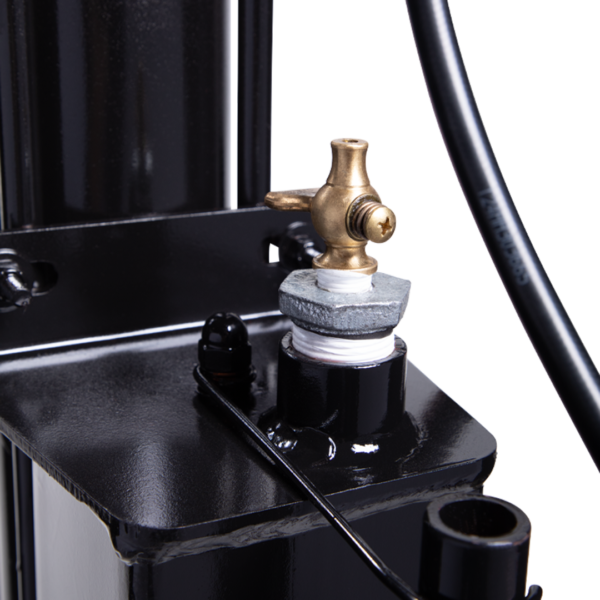

Temporarily plugging a pressurized pipe with the Hydra-Stopper Line Stop Machine, combined with the HSF 250 Line Stop Fitting, starts with a single circular hole — commonly known as a “tap” — cut into the top of the pipe without the need to ream or sever the pipe. After the work is completed, simply remove the line stop machine and attach a completion plug.

Hydra-Stop’s low-cost, lightweight Hydra-Stopper isolates a section of pressurized pipe for repair, maintenance or replacement of valves and hydrants in minutes, eliminating system shutdowns and saving time and money on repairs and maintenance.