Fixing a pothole shouldn’t require closing every city street. Likewise, repairing a single pipe in a community’s water supply shouldn’t mean that the entire system has to be turned off. Traffic can be routed around any construction work with a few signs. Nonetheless, isolating a water main in need of repair is a bit more complicated. This is where line stopping comes into play.

Municipalities and utilities rely on the procedure for repairing old or damaged portions of their water infrastructure. The process isolates pipes that need to be fixed or replaced while keeping the rest of the system in operation. Without line stopping, such work could have a much larger impact on customers and operators.

Here is a brief overview of how line stopping works and why it is necessary.

Why Line Stopping May Be Needed

When a main needs repair, water can’t be flowing through it. The extremely high pressure of fluid in the system makes it dangerous for contractors to work on pipes while in operation. One option is to shut down the entire system. However, this brings with it a number of problems. Not only would it cut off water service to countless customers, but it also might lead to possible contamination, backflow and boil orders. Simply put, shutting off the system could cost a municipality or utility far more than the price of the repairs.

For communities with aging or outdated infrastructure, the prospect of repairing or replacing large portions of the system may seem nearly impossible. Shutting down the system for as long as it would take to replace everything just wouldn’t be an option.

How Line Stopping Works

On the other hand, line stopping enables repairs or replacement of water mains without the need to turn off the entire system. A typical line-stopping procedure looks like this:

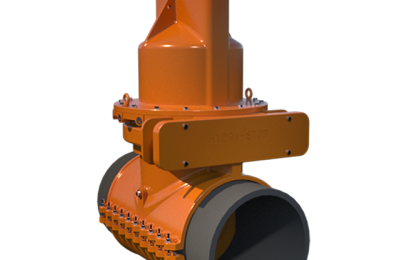

- A line-stop fitting and temporary valve are attached to the pipe in need of repair or replacement.

- The pipe is tapped and the tapping machine is removed.

- A solid plug is put in place, after which the crews can do any necessary work on the isolated section of pipe.

- The line-stop machine is removed and a completion plug and flange is placed on the pipe. The water system continues to function throughout the process, so customers continue to receive service.

The Benefits of Line Stopping

The line-stopping process can be utilized in a number of applications on almost any type of pipe that carries fluid under pressure. It can be used to replace valves, upgrade fire hydrants, install control valves, reline pipes and many other infrastructure improvements. Line stopping does more than save money. It also keeps repair crews and operators safe while enabling them to repair and upgrade vital infrastructure.

To learn more about the line-stopping process and the fittings used for it, contact the experts at Hydra-Stop today.